Understanding Double Shaft Crushers: Key Features and Benefits

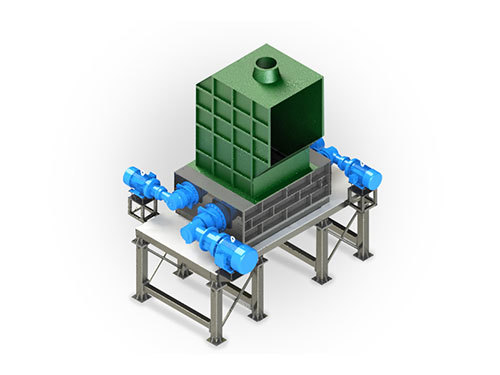

Double shaft crushers are powerful machines designed for the efficient breakdown of various materials. These crushers utilize a dual-shaft mechanism that allows for enhanced performance in the crushing process. The design typically consists of two rotating shafts, each equipped with heavy-duty blades or cutting tools. This dual-action system enables the crusher to handle tougher materials more effectively, making it an ideal choice for industries that require robust crushing solutions.

One of the primary advantages of using a double shaft crusher is its ability to produce a uniform particle size during processing. As the two shafts rotate in opposite directions, they create a shearing action that breaks down materials without excessive dust production. This feature is particularly beneficial in applications where maintaining a clean working environment is crucial, such as in recycling facilities or production plants.

In addition to size reduction, double shaft crushers excel in their versatility. They can process a wide range of materials, including plastics, wood, rubber, and even construction debris. This adaptability makes them suitable for various industries, from waste management to manufacturing, where different types of materials may need to be processed simultaneously.

Another notable characteristic of double shaft crushers is their robust construction. Built to withstand heavy loads and continuous operation, these machines are often designed with high-quality materials and components that ensure longevity and reliability. The dual-shaft design also contributes to their stability during operation, reducing vibrations and enhancing overall efficiency.

Maintenance of double shaft crushers is relatively straightforward, which is an essential consideration for companies looking to minimize downtime. Regular inspections and routine maintenance can keep the machine operating smoothly, ensuring consistent performance and extending its lifespan. Additionally, manufacturers often provide guidance on best practices for operating these machines, which can further enhance their operational efficiency.

When integrating a double shaft crusher into your production line, it is essential to consider the specific requirements of your application. Factors such as material type, size, and desired output should guide your choice of equipment. Consulting with technical experts can also help you understand the ideal configurations and settings to optimize the machine’s performance.

In summary, double shaft crushers are an invaluable asset in the manufacturing and processing machinery sector. Their robust design, versatility, and ability to maintain a clean work environment make them suitable for a wide range of applications. By understanding the features and benefits of double shaft crushers, businesses can make informed decisions that enhance their material processing capabilities.

One of the primary advantages of using a double shaft crusher is its ability to produce a uniform particle size during processing. As the two shafts rotate in opposite directions, they create a shearing action that breaks down materials without excessive dust production. This feature is particularly beneficial in applications where maintaining a clean working environment is crucial, such as in recycling facilities or production plants.

In addition to size reduction, double shaft crushers excel in their versatility. They can process a wide range of materials, including plastics, wood, rubber, and even construction debris. This adaptability makes them suitable for various industries, from waste management to manufacturing, where different types of materials may need to be processed simultaneously.

Another notable characteristic of double shaft crushers is their robust construction. Built to withstand heavy loads and continuous operation, these machines are often designed with high-quality materials and components that ensure longevity and reliability. The dual-shaft design also contributes to their stability during operation, reducing vibrations and enhancing overall efficiency.

Maintenance of double shaft crushers is relatively straightforward, which is an essential consideration for companies looking to minimize downtime. Regular inspections and routine maintenance can keep the machine operating smoothly, ensuring consistent performance and extending its lifespan. Additionally, manufacturers often provide guidance on best practices for operating these machines, which can further enhance their operational efficiency.

When integrating a double shaft crusher into your production line, it is essential to consider the specific requirements of your application. Factors such as material type, size, and desired output should guide your choice of equipment. Consulting with technical experts can also help you understand the ideal configurations and settings to optimize the machine’s performance.

In summary, double shaft crushers are an invaluable asset in the manufacturing and processing machinery sector. Their robust design, versatility, and ability to maintain a clean work environment make them suitable for a wide range of applications. By understanding the features and benefits of double shaft crushers, businesses can make informed decisions that enhance their material processing capabilities.

double shaft crusher

News

Center

Contact us

Maanshan shengzhong heavy industry machinery co.,Ltd.

Address: Bowang Economic Development Zone, Bowang New District, Ma'anshan City, Anhui Province

Tel: 0555-6765308

Mobile: +8615385558866