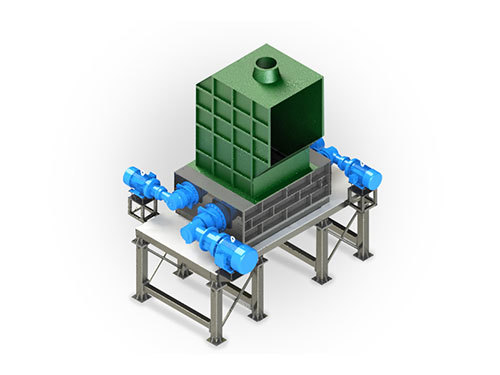

Four Shaft Shredder

Brand: Saint Forge

Through the feeding system, it enters the inside of the shredding box. There are four sets of blades on the box. The material is crushed by the comprehensive force of blade tearing and extrusion. When the size of the material is smaller than the screen hole, the material is crushed by gravity and extrusion. Under the action of force, it is discharged from the screen hole in the lower part of the box, and the larger material will continue to remain in the crushing cavity to be crushed until the size is smaller than the screen hole.

(The chain plate conveyor transports the large garbage to the crusher, and crushes it into smaller size materials. The iron remover sorts out metals such as iron wire and iron sheet. Other materials are packaged and transported or sent directly to the garbage truck. The whole production line is equipped with professional The dust suppression system realizes the rapid transfer of garbage, effective volume reduction, and reasonable classification and treatment.)

Product introduction

Product application: The four-shaft shredder is mainly used for shredding solid wastes such as domestic waste, industrial waste, electronic waste, waste plastic, and waste metal to achieve volume reduction and secondary recycling.

Quality Management System Certification

EU CE certification

Multiple patent certifications

Product advantages

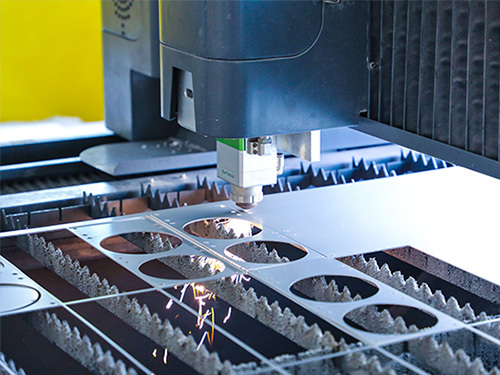

Shredder shaft

Wear-resistant coating for handling harder materials. The gap between the movable knife and the fixed knife can be easily adjusted. The movable knife adopts heat-treated DC53 die steel.

Shredder shaft

Wear-resistant coating for handling harder materials. The gap between the movable knife and the fixed knife can be easily adjusted. The movable knife adopts heat-treated DC53 die steel.

Shredder shaft

Wear-resistant coating for handling harder materials. The gap between the movable knife and the fixed knife can be easily adjusted. The movable knife adopts heat-treated DC53 die steel.

Shredder shaft

Wear-resistant coating for handling harder materials. The gap between the movable knife and the fixed knife can be easily adjusted. The movable knife adopts heat-treated DC53 die steel.

Technical parameter

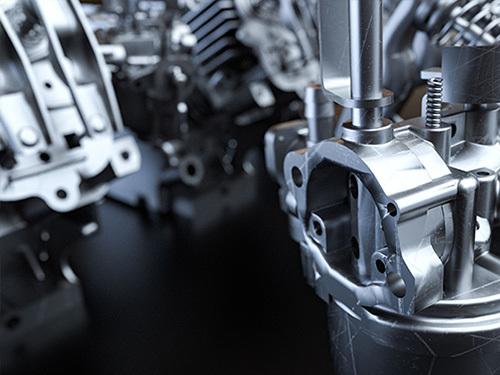

① Vehicle accessories: scrap tires, wheel hubs, oil filters, engine casings, scrap copper and aluminum parts, scrap steel plates and scrap iron forklift pallets with a thickness of less than 10mm

② Barrel products: plastic barrels, metal barrels, paint barrels, IBC barrels, trash cans, packaging barrels

③ Metal products: various scrap metal materials such as aluminum profiles, cans, metal cans, scrap aluminum sheets, scrap steel materials, iron sheets, copper sheets, etc.

④ Garbage: domestic waste, kitchen waste, industrial waste, garden waste

⑤ Plastic products: plastic pipes, pipe fittings, plastic bottles, plastic frames, plastic blocks, plastic tanks, rolled films, woven bags

⑥ Wooden paper: branches, stumps, building templates, wood blocks, newspapers, cardboard, corrugated paper, copy paper

⑦ Electronic appliances: refrigerator shells, circuit boards, computer shells, CD discs, waste TV sets, washing machines

⑧ Glass products: glass wool, glass cups, glass fiber reinforced plastic products

⑨ Medical waste: small medical equipment, clinical waste, pharmaceutical waste, infectious waste, various plastic waste, latex material waste, syringe waste

Customer case

Factory environment