The Science Behind Shredding: Understanding Plastic Scrap Shredder Machines

The Science Behind Shredding: Understanding Plastic Scrap Shredder Machines

Table of Contents

- 1. Introduction to Plastic Scrap Shredder Machines

- 2. The Importance of Shredding in Recycling Processes

- 3. How Plastic Scrap Shredder Machines Work

- 4. Types of Plastic Scrap Shredders

- 5. Key Features of High-Quality Shredder Machines

- 6. Applications of Plastic Scrap Shredders

- 7. Sustainability and the Future of Shredding Technology

- 8. Common Misconceptions About Plastic Shredders

- 9. FAQs

- 10. Conclusion

1. Introduction to Plastic Scrap Shredder Machines

In the rapidly evolving landscape of waste management and recycling, **plastic scrap shredder machines** play a pivotal role. These machines are designed to break down large volumes of plastic waste into smaller, manageable pieces, facilitating easier transportation and recycling. Understanding the complexities behind these machines not only sheds light on their functionality but also highlights their significance in promoting a sustainable environment.

2. The Importance of Shredding in Recycling Processes

Shredding is a critical process in recycling as it enhances the efficiency of material recovery. By reducing plastic waste into smaller particles, shredders allow for:

- Improved processing and sorting: Smaller pieces can be easily sorted and processed, ensuring higher quality recycling.

- Increased surface area: Shredded materials have a larger surface area, which aids in melting and remolding processes during recycling.

- Cost-effectiveness: Shredders minimize waste transportation costs by reducing the volume of materials.

Incorporating shredders into recycling operations not only streamlines the process but also maximizes the potential for reusing valuable plastics.

3. How Plastic Scrap Shredder Machines Work

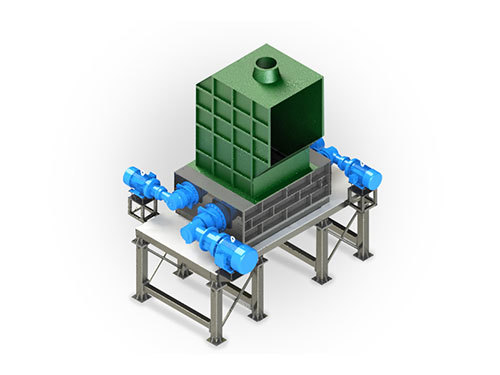

Understanding the mechanics of plastic scrap shredders involves exploring their core components and functions. Typically, these machines consist of:

- **Feeding system**: This system takes in the plastic waste and directs it into the cutting chamber.

- **Cutting chamber**: Equipped with sharp blades, the cutting chamber is where the shredding action takes place. The design and configuration of blades vary based on the machine's purpose.

- **Drive system**: This component powers the blades, usually via electric or hydraulic motors, ensuring efficient operation.

- **Screening and collection**: After shredding, materials pass through a screen that determines the size of the shredded output, which is then collected for further processing.

The intricate interplay of these components allows shredders to effectively tackle various types of plastic waste, from bottles to industrial scrap.

4. Types of Plastic Scrap Shredders

Different applications necessitate different types of shredders. The most common types include:

4.1 Single-Shaft Shredders

Single-shaft shredders utilize a single rotating blade to shred materials. They are ideal for plastic, wood, and metal materials, offering versatility in handling various waste types.

4.2 Double-Shaft Shredders

These shredders employ two shafts with intermeshing blades to cut materials. They are renowned for their ability to handle tougher materials and are often used in industrial applications.

4.3 Granulators

Granulators are designed to produce smaller granules from shredded plastic. They are often used in conjunction with shredders to achieve the desired particle size for recycling.

5. Key Features of High-Quality Shredder Machines

When selecting a plastic scrap shredder, several features distinguish high-quality machines:

5.1 Robust Construction

Durability is paramount. High-quality shredders are built with strong materials that can withstand rigorous use.

5.2 Versatile Blade Configuration

The ability to customize blade sizes and shapes allows for optimized shredding based on material type, enhancing efficiency.

5.3 Energy Efficiency

Modern shredders are designed to consume less energy while maintaining high performance, making them cost-effective and environmentally friendly.

5.4 Safety Features

Safety is crucial in any industrial machinery. Look for shredders equipped with emergency stop functions and protective covers to ensure operator safety.

6. Applications of Plastic Scrap Shredders

Plastic scrap shredders find applications across various industries:

6.1 Recycling Facilities

Recycling plants utilize shredders to process plastic waste, ensuring that materials can be reused in manufacturing new products.

6.2 Manufacturing Industries

Manufacturers often use shredders to recycle off-cuts and defective products, maximizing material utilization.

6.3 Waste Management Companies

Waste management firms deploy shredders to reduce the volume of waste, making transportation and disposal more manageable.

7. Sustainability and the Future of Shredding Technology

The future of shredding technology is closely tied to sustainability initiatives. Innovations in shredder design and operation are focused on reducing environmental impact:

- **Enhanced Recycling Rates**: Technological advancements are resulting in higher recycling rates, with shredders capable of processing more complex materials.

- **Integration with Smart Technology**: Smart shredders equipped with IoT technology can monitor performance and efficiency, leading to proactive maintenance and reduced downtime.

- **Closed-Loop Systems**: Companies are increasingly adopting closed-loop systems where shredded plastics are reused in the same production line, minimizing waste.

8. Common Misconceptions About Plastic Shredders

Despite their importance, several misconceptions about plastic shredders persist:

8.1 Shredders Are Only for Large Operations

While industrial shredders are common, smaller shredders are available for local businesses and households, promoting recycling at all levels.

8.2 All Shredders Are the Same

Shredders vary significantly in design and capability. Selecting the right shredder for specific applications is crucial for efficiency and effectiveness.

8.3 Shredding Plastics Creates Waste

On the contrary, shredding is a key step in recycling that reduces waste volume and facilitates material recovery.

9. FAQs

What types of plastics can be processed by shredders?

Plastic scrap shredders can process a wide variety of plastics, including PET, HDPE, PVC, and LDPE.

How do I choose the right shredder for my needs?

Consider factors such as material type, volume of waste, desired particle size, and machine features when selecting a shredder.

Are plastic shredders expensive to operate?

While initial costs can vary, energy-efficient models can significantly lower operating costs over time.

Can shredders be used for other materials besides plastic?

Yes, many shredders are versatile and can handle materials such as wood, metal, and electronic waste.

What maintenance do shredders require?

Regular maintenance includes checking blade sharpness, inspecting drive systems, and ensuring safety features are operational.

10. Conclusion

Understanding the science behind plastic scrap shredders reveals their fundamental role in recycling and waste management. As industries continue to evolve towards sustainability, the importance of efficient shredding technology cannot be overstated. By investing in high-quality shredders and embracing advancements in technology, businesses can contribute to a more sustainable future while optimizing their operations. This comprehensive understanding of shredding machines not only enhances operational efficiency but also fosters a commitment to environmental responsibility.

plastic scrap shredder machine

News

Center

Contact us

Maanshan shengzhong heavy industry machinery co.,Ltd.

Address: Bowang Economic Development Zone, Bowang New District, Ma'anshan City, Anhui Province

Tel: 0555-6765308

Mobile: +8615385558866