Maximizing Efficiency with Double Shaft Shredders: A Comprehensive Guide

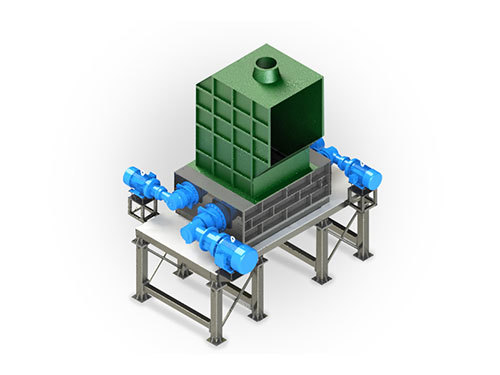

Double shaft shredders are essential machines in the field of manufacturing and processing, particularly for waste management and recycling operations. Unlike single shaft shredders, which utilize a single rotating blade, double shaft shredders employ two shafts that rotate in opposite directions. This unique design allows for a more effective shredding process, capable of handling a wide range of materials, from plastics and metals to wood and electronic waste.

One of the most significant advantages of double shaft shredders is their versatility. These machines can be configured to handle various input sizes and types, making them suitable for diverse industries. The two shafts enable a consistent shredding action, ensuring that materials are evenly processed and reducing the risk of jamming. This design also minimizes wear and tear on the machine, leading to lower maintenance costs over time.

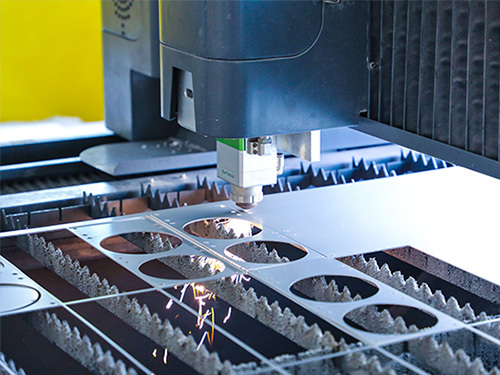

In terms of operation, double shaft shredders function by employing a series of robust blades mounted on each shaft. As the shafts rotate, the blades interlock, pulling materials into the shredding chamber where they are cut and fragmented. The resulting output size can be controlled by adjusting the distance between the shafts and the blade configuration. This adaptability allows manufacturers to produce specific particle sizes tailored to their requirements, whether for recycling purposes or for easier handling and disposal.

Moreover, double shaft shredders are designed with safety and efficiency in mind. Many models are equipped with advanced features such as automatic load sensing, which adjusts the motor power based on the material being processed. This not only optimizes energy consumption but also enhances performance. Additionally, these machines can include safety mechanisms to prevent overloading and protect operators during operation.

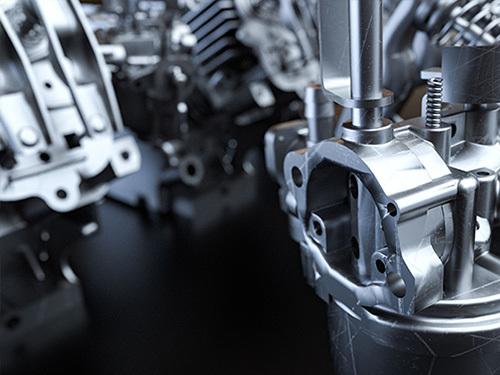

Applications for double shaft shredders are vast and varied. They are commonly used in recycling plants for processing scrap materials, in waste management for reducing the volume of waste, and even in the manufacturing sector for preparing materials for further processing. Industries such as automotive, construction, and electronics benefit greatly from the capabilities of double shaft shredders, as they provide an efficient solution for managing complex materials that require high levels of shredding.

In conclusion, double shaft shredders are a vital component in modern manufacturing and recycling processes. Their versatility, efficiency, and robust design make them a preferred choice for businesses looking to enhance their operations. By integrating a double shaft shredder into your workflow, you can streamline material handling, reduce waste, and ultimately improve productivity in your manufacturing processes.

One of the most significant advantages of double shaft shredders is their versatility. These machines can be configured to handle various input sizes and types, making them suitable for diverse industries. The two shafts enable a consistent shredding action, ensuring that materials are evenly processed and reducing the risk of jamming. This design also minimizes wear and tear on the machine, leading to lower maintenance costs over time.

In terms of operation, double shaft shredders function by employing a series of robust blades mounted on each shaft. As the shafts rotate, the blades interlock, pulling materials into the shredding chamber where they are cut and fragmented. The resulting output size can be controlled by adjusting the distance between the shafts and the blade configuration. This adaptability allows manufacturers to produce specific particle sizes tailored to their requirements, whether for recycling purposes or for easier handling and disposal.

Moreover, double shaft shredders are designed with safety and efficiency in mind. Many models are equipped with advanced features such as automatic load sensing, which adjusts the motor power based on the material being processed. This not only optimizes energy consumption but also enhances performance. Additionally, these machines can include safety mechanisms to prevent overloading and protect operators during operation.

Applications for double shaft shredders are vast and varied. They are commonly used in recycling plants for processing scrap materials, in waste management for reducing the volume of waste, and even in the manufacturing sector for preparing materials for further processing. Industries such as automotive, construction, and electronics benefit greatly from the capabilities of double shaft shredders, as they provide an efficient solution for managing complex materials that require high levels of shredding.

In conclusion, double shaft shredders are a vital component in modern manufacturing and recycling processes. Their versatility, efficiency, and robust design make them a preferred choice for businesses looking to enhance their operations. By integrating a double shaft shredder into your workflow, you can streamline material handling, reduce waste, and ultimately improve productivity in your manufacturing processes.

double shaft shredder

News

Center

Contact us

Maanshan shengzhong heavy industry machinery co.,Ltd.

Address: Bowang Economic Development Zone, Bowang New District, Ma'anshan City, Anhui Province

Tel: 0555-6765308

Mobile: +8615385558866