Exploring the Benefits of Small Shredders for Plastic Processing

In today's manufacturing landscape, the importance of efficient waste management and recycling is more significant than ever. One crucial piece of equipment that has gained popularity in this regard is the small shredder for plastic. This type of machine plays a vital role in reducing plastic waste and streamlining the recycling process, making it an invaluable asset for businesses engaged in plastic manufacturing and processing.

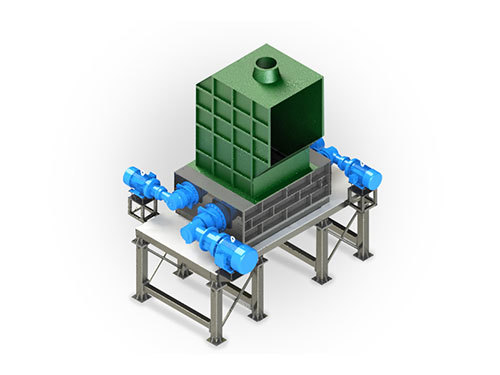

Small shredders for plastic are designed to break down various types of plastic materials into smaller, manageable pieces. This process not only aids in the recycling of plastics but also prepares them for further processing. By reducing plastic waste into smaller fragments, these shredders make it easier to transport, handle, and repurpose materials. This is particularly beneficial for companies looking to implement sustainable practices in their operations.

One of the primary advantages of using a small shredder for plastic is its versatility. These machines can handle a variety of plastic types, including polyethylene, polypropylene, and PVC. Whether you’re dealing with plastic bottles, containers, or other forms of plastic waste, a small shredder can efficiently process these materials, allowing for greater flexibility in your operations.

Another significant benefit is the energy efficiency of small shredders. Compared to larger industrial shredders, these machines typically consume less power while still delivering effective performance. This energy efficiency can lead to lower operational costs and a reduced carbon footprint, aligning with the growing emphasis on sustainability within the manufacturing sector.

Ease of use and maintenance are also critical factors that make small shredders appealing. Many models are designed with user-friendly features, allowing operators to easily control the shredding process. Regular maintenance is manageable, ensuring that the equipment remains in optimal working condition without extensive downtime. This reliability is crucial for businesses that rely on consistent and efficient production cycles.

Moreover, small shredders contribute to improving safety in the workplace. By reducing the size of plastic waste, these machines minimize the risk of accidents associated with handling large, unwieldy pieces of plastic. Additionally, many models come equipped with safety features that protect operators during the shredding process.

In summary, small shredders for plastic offer numerous benefits that can enhance efficiency and sustainability in manufacturing and recycling practices. Their versatility, energy efficiency, ease of use, and safety features make them an essential tool for businesses looking to improve their waste management processes and contribute to a more sustainable future. Investing in a small shredder for plastic can not only streamline operations but also support broader environmental goals, making it a smart choice for industries dealing with plastic materials.

Small shredders for plastic are designed to break down various types of plastic materials into smaller, manageable pieces. This process not only aids in the recycling of plastics but also prepares them for further processing. By reducing plastic waste into smaller fragments, these shredders make it easier to transport, handle, and repurpose materials. This is particularly beneficial for companies looking to implement sustainable practices in their operations.

One of the primary advantages of using a small shredder for plastic is its versatility. These machines can handle a variety of plastic types, including polyethylene, polypropylene, and PVC. Whether you’re dealing with plastic bottles, containers, or other forms of plastic waste, a small shredder can efficiently process these materials, allowing for greater flexibility in your operations.

Another significant benefit is the energy efficiency of small shredders. Compared to larger industrial shredders, these machines typically consume less power while still delivering effective performance. This energy efficiency can lead to lower operational costs and a reduced carbon footprint, aligning with the growing emphasis on sustainability within the manufacturing sector.

Ease of use and maintenance are also critical factors that make small shredders appealing. Many models are designed with user-friendly features, allowing operators to easily control the shredding process. Regular maintenance is manageable, ensuring that the equipment remains in optimal working condition without extensive downtime. This reliability is crucial for businesses that rely on consistent and efficient production cycles.

Moreover, small shredders contribute to improving safety in the workplace. By reducing the size of plastic waste, these machines minimize the risk of accidents associated with handling large, unwieldy pieces of plastic. Additionally, many models come equipped with safety features that protect operators during the shredding process.

In summary, small shredders for plastic offer numerous benefits that can enhance efficiency and sustainability in manufacturing and recycling practices. Their versatility, energy efficiency, ease of use, and safety features make them an essential tool for businesses looking to improve their waste management processes and contribute to a more sustainable future. Investing in a small shredder for plastic can not only streamline operations but also support broader environmental goals, making it a smart choice for industries dealing with plastic materials.

small shredder for plastic

News

Center

Contact us

Maanshan shengzhong heavy industry machinery co.,Ltd.

Address: Bowang Economic Development Zone, Bowang New District, Ma'anshan City, Anhui Province

Tel: 0555-6765308

Mobile: +8615385558866