What You Need to Know About Double Shaft Crusher Technology

What You Need to Know About Double Shaft Crusher Technology

Introduction to Double Shaft Crushers

Double shaft crushers are pivotal in the world of manufacturing and processing machinery, particularly in the field of material reduction. Their unique design and operational efficiency make them indispensable for industries such as waste management, recycling, and aggregate production. This article delves into the intricacies of double shaft crusher technology, emphasizing its importance, functionality, and benefits.

Understanding the Mechanism of Double Shaft Crushers

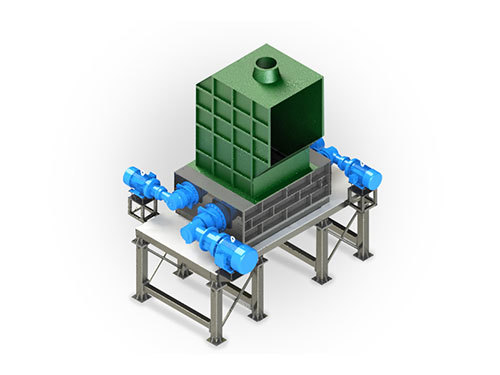

The Basic Structure of Double Shaft Crushers

At the heart of double shaft crushers lies the dual-shaft design. Two parallel shafts equipped with sharp blades rotate at different speeds, effectively tearing and crushing materials. This design allows for a powerful crushing action while maintaining a consistent output size. The **heavy-duty construction** of the machine ensures durability and longevity, making it suitable for demanding industrial applications.

How Double Shaft Crushers Operate

The operation of double shaft crushers is relatively straightforward. As materials are fed into the machine, the rotating shafts create a shearing effect, breaking down the material into smaller particles. The unique arrangement of the blades ensures that the materials are evenly processed, resulting in a uniform output that meets industry standards.

Key Advantages of Double Shaft Crusher Technology

1. Enhanced Material Reduction Efficiency

One of the standout features of double shaft crushers is their ability to handle various materials, including hard and soft substances. The dual-shaft mechanism allows for a more efficient reduction of material size compared to single-shaft models. This efficiency translates to less energy consumption and reduced operational costs.

2. Versatility in Applications

Double shaft crushers are incredibly versatile. They can be used across a range of industries, including **waste management**, **recycling**, **construction**, and **mining**. Whether reducing rubber, plastics, or metals, these crushers adapt to different materials and applications, making them a go-to solution for many businesses.

3. Improved Safety Features

Safety is paramount in any manufacturing environment. Double shaft crushers are designed with safety in mind, equipped with features such as overload protection and emergency stop functions. These safety mechanisms ensure that operations can be conducted without undue risk to personnel and equipment.

4. Reduced Noise and Vibration Levels

Unlike some other crushing technologies, double shaft crushers operate at lower noise and vibration levels, contributing to a more pleasant working environment. This feature is particularly beneficial in urban settings or during operations where noise regulations must be adhered to.

Applications of Double Shaft Crushers

In the Recycling Industry

In recycling facilities, double shaft crushers are essential for breaking down materials such as plastics, metals, and electronic waste. Their ability to process mixed materials quickly and efficiently makes them ideal for recycling operations, leading to higher recovery rates and reduced landfill waste.

In Waste Management

Waste management services utilize double shaft crushers to reduce the volume of waste before it is sent for further processing or landfilling. By shredding waste materials, these machines help improve the efficiency of waste handling and transport, ultimately optimizing the overall waste management process.

In Construction and Demolition

The construction industry often finds double shaft crushers useful in the demolition of structures. By crushing and processing concrete and metal waste, construction companies can recycle materials, reducing the environmental impact of their activities and saving costs on new material procurement.

Maintenance and Care for Double Shaft Crushers

Regular Inspections

To ensure optimal performance, regular inspections of double shaft crushers are necessary. Operators should check for wear and tear on blades, monitor hydraulic systems, and ensure that all safety features are functional. Routine maintenance not only extends the life of the machinery but also ensures consistent output quality.

Blade Replacement and Sharpening

The blades of double shaft crushers are subject to wear over time. Regular sharpening or replacement of these blades is crucial for maintaining the efficiency of the machine. Operators should adhere to manufacturer guidelines regarding blade care to minimize downtime and maintain productivity.

Lubrication and Hydraulic Maintenance

Proper lubrication of moving parts is essential for the longevity of double shaft crushers. Regularly checking hydraulic systems for leaks and maintaining appropriate fluid levels can prevent mechanical failures and ensure smooth operation.

Cost Considerations for Double Shaft Crushers

Initial Investment vs. Long-Term Savings

While the initial cost of investing in a double shaft crusher may seem high, the machine's efficiency and durability offer long-term savings. Reduced operational costs, lower maintenance expenses, and the ability to process various materials contribute to a favorable return on investment.

Factors Influencing Cost

Several factors influence the overall cost of double shaft crushers, including size, capacity, and additional features. Businesses should assess their specific needs and choose a model that offers the best balance between performance and cost.

Future of Double Shaft Crusher Technology

Advancements in Design and Performance

As technology advances, so too will the design and performance of double shaft crushers. Innovations in materials, automation, and energy efficiency are on the horizon, promising even greater efficiency and reliability in the future.

Integration with Smart Technology

The future of double shaft crushers may also see greater integration with smart technology. IoT-enabled machines that provide real-time data on performance, maintenance needs, and energy consumption can help operators make informed decisions, further enhancing operational efficiency.

FAQs About Double Shaft Crushers

What materials can double shaft crushers handle?

Double shaft crushers can process a wide range of materials, including plastics, metals, rubber, and organic waste, making them highly versatile for various industries.

How do I select the right double shaft crusher for my needs?

Consider factors such as material type, desired output size, and operational capacity when selecting a double shaft crusher. Consulting with manufacturers can also provide insights into the most suitable model for your specific requirements.

What is the average lifespan of a double shaft crusher?

With proper maintenance and care, double shaft crushers can last several years, often exceeding a decade, depending on usage and operating conditions.

Can double shaft crushers help reduce operational costs?

Yes, their efficiency in material processing and reduced energy consumption can lead to significant operational cost savings over time.

Are there safety features built into double shaft crushers?

Yes, most double shaft crushers come equipped with safety features such as overload protection, emergency stops, and safety guards to ensure safe operation.

Conclusion

Double shaft crusher technology represents a critical advancement in the manufacturing and processing machinery industry. With their unique design, efficiency, versatility, and safety features, these machines play a vital role in various sectors, from recycling to waste management. Understanding their mechanisms, benefits, and maintenance requirements can help businesses make informed decisions about their equipment needs. As technology continues to evolve, double shaft crushers will undoubtedly adapt, paving the way for a more efficient and sustainable future in material processing.

double shaft crusher

News

Center

Contact us

Maanshan shengzhong heavy industry machinery co.,Ltd.

Address: Bowang Economic Development Zone, Bowang New District, Ma'anshan City, Anhui Province

Tel: 0555-6765308

Mobile: +8615385558866