Understanding Double Shaft Crushers: A Comprehensive Guide for the Manufacturing Industry

Double shaft crushers are essential machinery in the field of material processing, specifically in the crushing and sorting sector. These machines are designed to handle various types of materials, including but not limited to plastics, metals, and other composites, providing versatility in recycling and waste management applications.

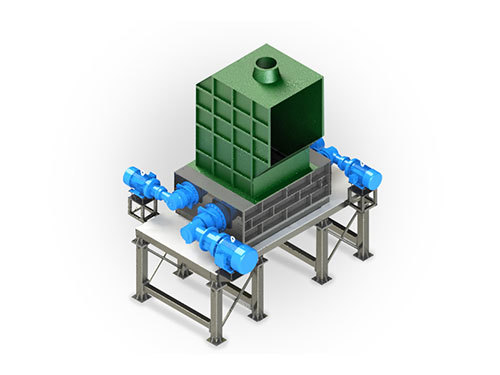

One of the key advantages of double shaft crushers is their ability to efficiently reduce material size. The design incorporates two shafts, each equipped with sharp blades or teeth that work in tandem to shred materials into smaller fragments. This dual-action mechanism not only increases the effectiveness of the crushing process but also minimizes the risk of material jamming, which is a common issue with single shaft models. The result is a smooth and continuous operation, making double shaft crushers an excellent choice for high-volume production environments.

Moreover, double shaft crushers are known for their robust construction, which allows them to withstand heavy-duty use. They are built to handle tough materials, which is particularly beneficial for industries that deal with hard or abrasive substances. The durability of these machines ensures a longer service life, reducing downtime and maintenance costs, which can be critical in maintaining a competitive edge in manufacturing.

Another significant aspect of double shaft crushers is their adaptability. These machines can be customized to meet specific processing needs, including adjustments in blade configuration, motor power, and feed size. This level of flexibility makes them suitable for various applications, from recycling electronic waste to processing large industrial components. Manufacturers can thus optimize their operations by deploying double shaft crushers tailored to their unique requirements.

In terms of safety, double shaft crushers are designed with several features to protect operators and minimize hazards. Many models come equipped with safety guards, emergency shut-off switches, and automatic overload protection systems. These features ensure that personnel can operate the machinery confidently, knowing that safety precautions are in place.

The environmental impact of using double shaft crushers is another essential consideration. By facilitating the recycling of materials, these machines contribute to waste reduction and promote sustainable practices within the manufacturing industry. The efficient crushing of recyclables not only conserves natural resources but also reduces the carbon footprint associated with new material production.

In conclusion, double shaft crushers play a vital role in the manufacturing and processing sectors. Their efficiency, durability, adaptability, and safety features make them indispensable tools for companies looking to enhance productivity and sustainability. Understanding the capabilities of double shaft crushers can help businesses make informed decisions and improve their material processing operations significantly.

One of the key advantages of double shaft crushers is their ability to efficiently reduce material size. The design incorporates two shafts, each equipped with sharp blades or teeth that work in tandem to shred materials into smaller fragments. This dual-action mechanism not only increases the effectiveness of the crushing process but also minimizes the risk of material jamming, which is a common issue with single shaft models. The result is a smooth and continuous operation, making double shaft crushers an excellent choice for high-volume production environments.

Moreover, double shaft crushers are known for their robust construction, which allows them to withstand heavy-duty use. They are built to handle tough materials, which is particularly beneficial for industries that deal with hard or abrasive substances. The durability of these machines ensures a longer service life, reducing downtime and maintenance costs, which can be critical in maintaining a competitive edge in manufacturing.

Another significant aspect of double shaft crushers is their adaptability. These machines can be customized to meet specific processing needs, including adjustments in blade configuration, motor power, and feed size. This level of flexibility makes them suitable for various applications, from recycling electronic waste to processing large industrial components. Manufacturers can thus optimize their operations by deploying double shaft crushers tailored to their unique requirements.

In terms of safety, double shaft crushers are designed with several features to protect operators and minimize hazards. Many models come equipped with safety guards, emergency shut-off switches, and automatic overload protection systems. These features ensure that personnel can operate the machinery confidently, knowing that safety precautions are in place.

The environmental impact of using double shaft crushers is another essential consideration. By facilitating the recycling of materials, these machines contribute to waste reduction and promote sustainable practices within the manufacturing industry. The efficient crushing of recyclables not only conserves natural resources but also reduces the carbon footprint associated with new material production.

In conclusion, double shaft crushers play a vital role in the manufacturing and processing sectors. Their efficiency, durability, adaptability, and safety features make them indispensable tools for companies looking to enhance productivity and sustainability. Understanding the capabilities of double shaft crushers can help businesses make informed decisions and improve their material processing operations significantly.

double shaft crusher

News

Center

Contact us

Maanshan shengzhong heavy industry machinery co.,Ltd.

Address: Bowang Economic Development Zone, Bowang New District, Ma'anshan City, Anhui Province

Tel: 0555-6765308

Mobile: +8615385558866