Enhancing Productivity: Integrating Plastic Scrap Shredder Machines in Your Workflow

Enhancing Productivity: Integrating Plastic Scrap Shredder Machines in Your Workflow

Table of Contents

- 1. Introduction to Plastic Scrap Shredder Machines

- 2. Importance of Shredding Plastic Scrap

- 3. Key Benefits of Integrating Shredder Machines

- 4. Different Types of Plastic Scrap Shredder Machines

- 5. Integrating Shredder Machines into Your Workflow

- 6. Maintenance and Care for Shredder Machines

- 7. Case Studies: Real-World Applications

- 8. The Future of Plastic Recycling and Shredding

- 9. Frequently Asked Questions

- 10. Conclusion

1. Introduction to Plastic Scrap Shredder Machines

The manufacturing sector has seen a significant shift towards efficiency and sustainability, with plastic scrap shredder machines taking center stage. These machines play a crucial role in recycling operations by reducing plastic waste into manageable sizes, preparing them for further processing. By integrating these machines into your workflow, you can not only enhance productivity but also contribute to a more sustainable environment.

2. Importance of Shredding Plastic Scrap

Plastic scrap is an inevitable byproduct of various manufacturing processes. The importance of shredding this waste cannot be overstated. Shredding reduces the volume of plastic materials, making them easier to store, transport, and recycle. Furthermore, effective shredding helps in reclaiming valuable materials that can be reused, thus promoting a circular economy.

Environmental Impact

Plastic waste poses a significant threat to our environment. By integrating plastic scrap shredder machines, manufacturers can significantly mitigate their environmental footprint. Shredded plastic is easier to recycle, leading to less landfill waste and reduced need for virgin plastic production.

Cost-Effectiveness

Implementing shredding solutions can lead to substantial cost savings. By converting scrap material into reusable forms, businesses can cut down on raw material costs and disposal fees. This shift not only enhances the bottom line but also promotes sustainability.

3. Key Benefits of Integrating Shredder Machines

Integrating plastic scrap shredder machines into your manufacturing workflow offers numerous benefits, including:

Increased Operational Efficiency

Shredder machines streamline the recycling process by quickly and efficiently processing large volumes of plastic scrap. This efficiency leads to shorter production cycles and minimized downtime, allowing businesses to focus on their core operations.

Improved Material Management

With effective shredding, managing plastic waste becomes much simpler. Shredded materials take up less space and can be easily transported to recycling facilities or reused in new production processes. This results in better inventory management and reduced storage costs.

Enhanced Product Quality

Using shredded plastic as a raw material can improve the quality of end products. The consistent size and quality of shredded materials enable manufacturers to maintain higher standards in their production processes.

4. Different Types of Plastic Scrap Shredder Machines

There is a range of plastic scrap shredder machines available, each designed for specific applications. Understanding the types can help you choose the right one for your workflow.

Granulator Shredders

Granulator shredders are ideal for producing small plastic flakes or granules. These machines are widely used in recycling facilities and are effective for processing a variety of plastic types.

Single-Shaft Shredders

Single-shaft shredders are versatile machines that can handle different types of plastic scrap. They are designed for continuous operation and are equipped with a robust cutting system that ensures a uniform output size.

Two-Shaft Shredders

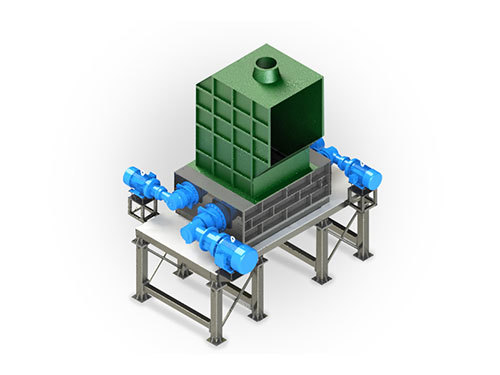

These machines are particularly effective for processing tougher materials. Two-shaft shredders use dual rotating blades to shred plastic scrap efficiently, making them suitable for heavy-duty applications.

Industrial Shredders

Industrial shredders are designed for large-scale operations and can handle significant volumes of plastic waste. These machines are robust and can shred various types of materials, making them an excellent choice for manufacturers with high scrap levels.

5. Integrating Shredder Machines into Your Workflow

Successful integration of plastic scrap shredder machines into your workflow requires strategic planning and execution. Here are some steps to consider:

Assess Current Processes

Evaluate your current waste management and production processes to identify areas where shredding can add value. Look for pain points such as excessive waste or high disposal costs.

Select the Right Shredder

Choose a shredder that aligns with your specific needs and production goals. Consider factors such as the type and volume of plastic scrap, desired output size, and available space.

Train Your Team

Training your staff on the operation and maintenance of shredders is crucial for maximizing efficiency. Ensure that your team understands the importance of proper usage and safety protocols.

Monitor and Optimize

Once integrated, continuously monitor the performance of your shredders. Analyze data to identify improvements and optimize your workflow for maximum productivity.

6. Maintenance and Care for Shredder Machines

Regular maintenance of your plastic scrap shredder machines is essential to ensure longevity and optimal performance. Here are some maintenance tips:

Routine Inspections

Conduct regular inspections to check for wear and tear on blades and components. Identify potential issues before they escalate, ensuring your machines operate smoothly.

Lubrication

Proper lubrication of moving parts is critical. Follow the manufacturer's recommendations on lubrication schedules to prevent friction and overheating.

Cleaning

Keep your shredder machines clean to prevent material buildup that can affect performance. Regular cleaning helps maintain efficiency and extends the life of the equipment.

7. Case Studies: Real-World Applications

Examining real-world applications of plastic scrap shredder machines can provide valuable insights into their effectiveness.

Case Study 1: Automotive Industry

An automotive manufacturer integrated a single-shaft shredder into their production line to process plastic waste from parts manufacturing. This integration led to a 30% reduction in waste disposal costs and improved recycling rates for their plastic components.

Case Study 2: Consumer Goods Sector

A leading consumer goods company adopted two-shaft shredders to handle post-consumer plastic packaging. This move allowed them to reclaim 50% more material for reuse, significantly enhancing their sustainability efforts.

8. The Future of Plastic Recycling and Shredding

As technology continues to evolve, the future of plastic recycling and shredding holds great promise. Innovations such as smart shredders equipped with sensors and AI technology can further enhance operational efficiency and material recovery rates.

Emphasis on Sustainability

The push for sustainability will drive advancements in shredding technology. As regulations become stricter, businesses will increasingly look to integrate advanced shredders to meet environmental goals.

Collaboration and Partnerships

Future success in plastic recycling will rely on collaborations between manufacturers, recyclers, and technology providers. Partnerships will foster innovation, creating efficient systems for managing plastic waste.

9. Frequently Asked Questions

What is a plastic scrap shredder machine?

A plastic scrap shredder machine is a device used to reduce plastic waste into smaller, manageable pieces, making it easier to recycle or reuse.

How do I choose the right shredder for my business?

Consider factors such as the type of plastic, the volume of scrap, desired output size, and your specific production needs when selecting a shredder.

What maintenance does a plastic shredder require?

Routine inspections, lubrication, and cleaning are essential maintenance tasks to ensure optimal performance and longevity of the shredder.

Can shredders help reduce waste disposal costs?

Yes, by converting plastic scrap into reusable forms, shredders can significantly reduce waste disposal costs and promote recycling efforts.

What are the environmental benefits of using plastic shredders?

Using plastic shredders helps decrease landfill waste, promotes material recovery, and reduces the need for virgin plastic production, contributing to a more sustainable environment.

10. Conclusion

Integrating plastic scrap shredder machines into your manufacturing workflow is a strategic move that enhances productivity while promoting sustainability. By effectively managing plastic waste, businesses can not only improve their operational efficiency but also contribute to a healthier planet. As the industry evolves, the role of shredders will become increasingly vital, paving the way for innovative recycling solutions and a more sustainable future.

plastic scrap shredder machine

News

Center

Contact us

Maanshan shengzhong heavy industry machinery co.,Ltd.

Address: Bowang Economic Development Zone, Bowang New District, Ma'anshan City, Anhui Province

Tel: 0555-6765308

Mobile: +8615385558866