Maximizing Efficiency in Plastic Waste Management: The Role of Plastic Scrap Shredder Machines

In today's industrial landscape, efficient waste management is crucial for sustainability and operational efficiency. One key component in achieving this is the plastic scrap shredder machine. These machines are designed to reduce plastic waste into manageable sizes, facilitating recycling processes and promoting environmental responsibility.

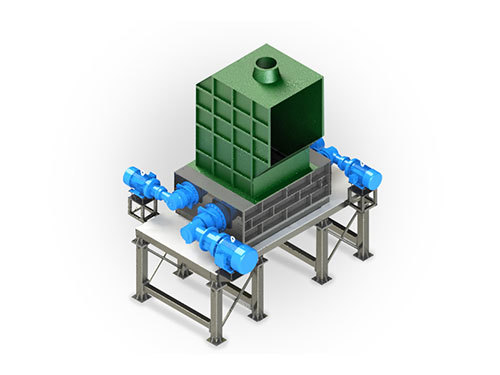

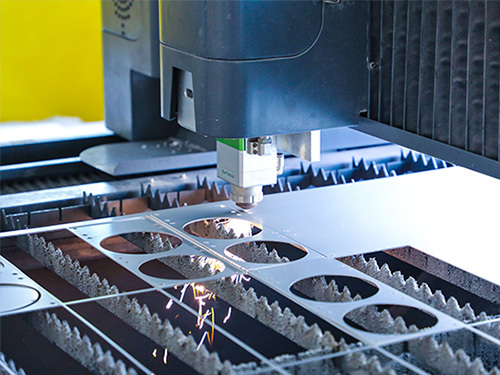

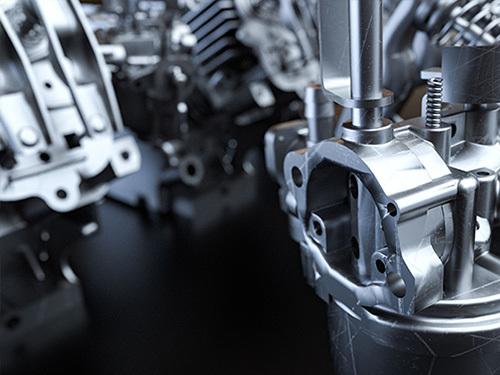

A plastic scrap shredder machine typically utilizes sharp blades and powerful motors to shred various types of plastic materials, including films, sheets, and post-consumer plastic products. By breaking down these materials, the machine allows for easier handling and processing, ultimately enhancing the recycling potential of the plastic waste.

One significant advantage of employing a plastic scrap shredder machine is its capability to optimize space. By reducing the volume of plastic waste, businesses can significantly decrease storage requirements, leading to better organization and lower disposal costs. Furthermore, shredding plastic scrap prepares it for further processing, such as granulation or extrusion, making it an essential step in the recycling chain.

In addition to space-saving benefits, these machines contribute to enhanced safety in the workplace. By shredding plastic waste, the risk of accidents related to handling large, bulky items is minimized. Employees can work in a safer environment, focusing on their core tasks without the distraction of cluttered waste.

Moreover, adopting a plastic scrap shredder machine can support a company’s sustainability initiatives. As industries face increasing pressure to reduce waste and improve recycling rates, the ability to efficiently process plastic scrap showcases a commitment to environmental stewardship. This not only improves a company's public image but may also meet regulatory requirements in an increasingly eco-conscious market.

When considering the integration of a plastic scrap shredder machine into operations, businesses must assess several factors. These include the type of plastic materials they commonly handle, the volume of scrap generated, and the desired output size of the shredded material. Ensuring that the machine is compatible with the specific kinds of plastics used in their production processes is vital for optimal performance.

In conclusion, plastic scrap shredder machines play a pivotal role in modern waste management strategies for manufacturers and processors. By reducing plastic waste to manageable sizes, these machines not only facilitate recycling but also enhance operational efficiency and workplace safety. As industries strive for more sustainable practices, investing in a plastic scrap shredder machine can be a significant step toward achieving those goals.

A plastic scrap shredder machine typically utilizes sharp blades and powerful motors to shred various types of plastic materials, including films, sheets, and post-consumer plastic products. By breaking down these materials, the machine allows for easier handling and processing, ultimately enhancing the recycling potential of the plastic waste.

One significant advantage of employing a plastic scrap shredder machine is its capability to optimize space. By reducing the volume of plastic waste, businesses can significantly decrease storage requirements, leading to better organization and lower disposal costs. Furthermore, shredding plastic scrap prepares it for further processing, such as granulation or extrusion, making it an essential step in the recycling chain.

In addition to space-saving benefits, these machines contribute to enhanced safety in the workplace. By shredding plastic waste, the risk of accidents related to handling large, bulky items is minimized. Employees can work in a safer environment, focusing on their core tasks without the distraction of cluttered waste.

Moreover, adopting a plastic scrap shredder machine can support a company’s sustainability initiatives. As industries face increasing pressure to reduce waste and improve recycling rates, the ability to efficiently process plastic scrap showcases a commitment to environmental stewardship. This not only improves a company's public image but may also meet regulatory requirements in an increasingly eco-conscious market.

When considering the integration of a plastic scrap shredder machine into operations, businesses must assess several factors. These include the type of plastic materials they commonly handle, the volume of scrap generated, and the desired output size of the shredded material. Ensuring that the machine is compatible with the specific kinds of plastics used in their production processes is vital for optimal performance.

In conclusion, plastic scrap shredder machines play a pivotal role in modern waste management strategies for manufacturers and processors. By reducing plastic waste to manageable sizes, these machines not only facilitate recycling but also enhance operational efficiency and workplace safety. As industries strive for more sustainable practices, investing in a plastic scrap shredder machine can be a significant step toward achieving those goals.

plastic scrap shredder machine

News

Center

Contact us

Maanshan shengzhong heavy industry machinery co.,Ltd.

Address: Bowang Economic Development Zone, Bowang New District, Ma'anshan City, Anhui Province

Tel: 0555-6765308

Mobile: +8615385558866