The Crucial Impact of Plastic Scrap Shredder Machines on Waste Reduction Initiatives

The Crucial Impact of Plastic Scrap Shredder Machines on Waste Reduction Initiatives

Introduction: Understanding the Plastic Waste Crisis

In today's world, the escalating issue of plastic waste poses a significant threat to our environment. As plastic products pervade nearly every aspect of modern life, the amount of waste generated continues to rise. To combat this crisis, innovative solutions are required, and **plastic scrap shredder machines** have emerged as crucial players in this waste reduction narrative. These machines not only facilitate the recycling process but also contribute to sustainable waste management practices that can significantly lessen plastic pollution globally.

Table of Contents

- 1. What Are Plastic Scrap Shredder Machines?

- 2. How Do Plastic Shredders Work?

- 3. Types of Plastic Scrap Shredder Machines

- 4. Benefits of Using Plastic Scrap Shredder Machines

- 5. Applications of Plastic Scrap Shredders in Various Industries

- 6. Environmental Impact of Plastic Scrap Shredding

- 7. Choosing the Right Plastic Scrap Shredder for Your Needs

- 8. Future Trends in Plastic Shredding Technology

- 9. Frequently Asked Questions (FAQs)

- 10. Conclusion

1. What Are Plastic Scrap Shredder Machines?

**Plastic scrap shredder machines** are industrial devices designed to reduce plastic materials into smaller, manageable pieces. This process not only makes the plastics easier to handle but also prepares them for recycling. Shredders can handle various types of plastic, including PET, HDPE, PVC, and more, making them versatile tools in waste management. By converting waste into smaller sizes, these machines play a pivotal role in facilitating the recycling process, thus promoting sustainability.

2. How Do Plastic Shredders Work?

The operation of plastic scrap shredders involves several technical processes. Initially, the plastic waste is fed into the shredding chamber, where it encounters rotating blades. These blades, designed with specific configurations, slice and crush the plastic into tiny pieces. The size of the output can vary based on the machine settings and the type of plastic being shredded. After shredding, the plastic pieces can be further processed for recycling or reused in various applications.

Key Components of Plastic Shredders

- **Blades:** Sharp, durable blades are crucial for efficient shredding.

- **Motor:** A powerful motor drives the blades, ensuring optimal performance.

- **Feed Hopper:** This is where the plastic waste is introduced into the machine.

- **Screen:** A screen regulates the size of the shredded output, promoting uniformity.

3. Types of Plastic Scrap Shredder Machines

Different types of plastic scrap shredders cater to various needs and applications. Understanding these types is essential for selecting the right machine for specific tasks.

3.1 Single Shaft Shredders

Single shaft shredders are prevalent in recycling facilities. They utilize a single rotating blade to shred plastic waste, offering versatility for various materials.

3.2 Two Shaft Shredders

These shredders feature two parallel shafts with interlocking blades. They are particularly effective for tougher plastics and can handle larger volumes of waste.

3.3 Granulators

Granulators are designed for producing smaller granules from shredded plastics. They are typically used in the final stages of the recycling process.

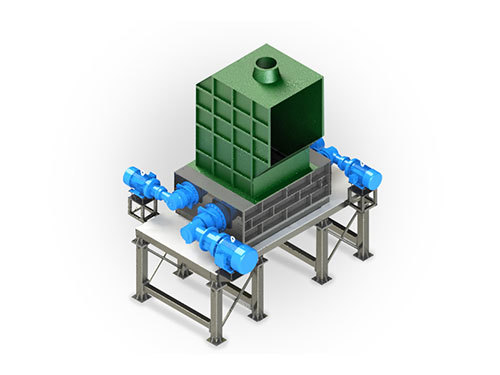

3.4 Industrial Shredders

Industrial shredders are heavy-duty machines capable of handling massive volumes of plastic waste. They are often used in large manufacturing environments.

4. Benefits of Using Plastic Scrap Shredder Machines

Investing in plastic scrap shredders comes with numerous advantages that significantly aid waste reduction efforts:

4.1 Enhanced Recycling Efficiency

Shredders facilitate the recycling process by reducing plastic waste into manageable pieces, promoting better processing and recycling rates.

4.2 Cost-Effective Waste Management

By effectively shredding plastic waste, businesses can lower disposal costs and reduce the environmental impact associated with landfill use.

4.3 Versatility in Material Handling

Plastic shredders can process a wide range of materials, making them suitable for various industries, from manufacturing to municipal waste management.

4.4 Promoting Sustainability

By integrating shredders into waste management practices, organizations contribute to a circular economy, reducing the need for virgin materials and minimizing environmental impact.

5. Applications of Plastic Scrap Shredders in Various Industries

Plastic scrap shredders find applications across numerous sectors, showcasing their versatility and importance in waste management.

5.1 Manufacturing

In manufacturing, shredded plastic can be reused as raw material, minimizing waste and promoting sustainability. This approach helps manufacturers meet corporate social responsibility (CSR) goals.

5.2 Packaging

Shredded plastic from packaging materials can be recycled into new products, reducing the demand for new plastic production and saving energy.

5.4 Automotive Industry

The automotive industry uses plastic components extensively. Shredders can process plastic waste from production lines, contributing to a more sustainable manufacturing process.

6. Environmental Impact of Plastic Scrap Shredding

The environmental benefits of utilizing plastic scrap shredders are profound:

6.1 Reducing Landfill Waste

By shredding plastic waste, less material ends up in landfills, decreasing the risk of soil and water contamination.

6.2 Lowering Carbon Footprint

Recycling shredded plastics typically requires less energy compared to producing new plastics, helping reduce greenhouse gas emissions.

6.3 Promoting Resource Recovery

Shredders enable the recovery of valuable materials, fostering a more sustainable approach to resource management.

7. Choosing the Right Plastic Scrap Shredder for Your Needs

Selecting the appropriate plastic scrap shredder involves considering several factors:

7.1 Material Type

Different machines are optimized for specific types of plastic. It’s essential to choose a shredder that matches your materials for optimal performance.

7.2 Volume of Waste

Assess your waste volume to determine the shredder’s capacity. Smaller operations may benefit from single shaft shredders, while larger facilities might require industrial models.

7.3 Budget

Evaluate your budget, balancing the cost of investment with the anticipated return on investment through efficiency gains and waste reduction.

8. Future Trends in Plastic Shredding Technology

As technology continues to advance, plastic shredders are evolving. Future trends may include:

8.1 Smart Shredding Solutions

Integrating IoT technology could enable shredders to monitor performance in real-time, optimizing operations and maintenance schedules.

8.2 Enhanced Energy Efficiency

Newer models may focus on reducing energy consumption, further promoting sustainability and lowering operational costs.

8.3 Eco-Friendly Designs

Manufacturers are likely to shift toward eco-friendly materials and designs, enhancing the environmental benefits of shredders.

9. Frequently Asked Questions (FAQs)

1. What types of plastic can be shredded?

Plastic scrap shredders can process various types of plastics, including PET, HDPE, PVC, and others.

2. How much noise do plastic shredders generate?

The noise level depends on the shredder type, but many modern machines are designed to minimize noise, often featuring soundproofing technology.

3. Can I shred non-plastic materials?

While primarily designed for plastic, some shredders can handle light metals or paper. However, always refer to the manufacturer’s guidelines.

4. Are plastic shredders easy to maintain?

Yes, most plastic shredders require minimal maintenance, but regular checks on blades and motors are recommended for optimal performance.

5. How do I ensure safety while using a plastic shredder?

Always follow safety guidelines provided by the manufacturer, including wearing appropriate protective gear and ensuring that safety features are functioning correctly.

10. Conclusion

Plastic scrap shredder machines play a vital role in waste reduction efforts, transforming plastic waste into valuable resources for recycling and reuse. As industries continue to grapple with the challenges posed by plastic waste, investing in these machines represents a crucial step towards achieving sustainability. The benefits of shredders, including enhanced recycling efficiency, cost reductions, and environmental protection, underscore their importance in modern waste management strategies. As we move forward, embracing the latest technological advancements in shredding will be essential for fostering an eco-friendly future.

plastic scrap shredder machine

News

Center

Contact us

Maanshan shengzhong heavy industry machinery co.,Ltd.

Address: Bowang Economic Development Zone, Bowang New District, Ma'anshan City, Anhui Province

Tel: 0555-6765308

Mobile: +8615385558866