Key Features to Look for in a Double Shaft Shredder

Key Features to Look for in a Double Shaft Shredder

Introduction to Double Shaft Shredders

In the world of waste management and recycling, double shaft shredders are recognized for their ability to handle a diverse range of materials. Unlike single shaft shredders, double shaft shredders utilize two parallel shafts that rotate in opposite directions, providing a more efficient and effective shredding process. This article delves into the **key features** that buyers should consider when selecting a double shaft shredder, ensuring optimal performance and longevity.

Table of Contents

- 1. Understanding the Mechanism of Double Shaft Shredders

- 2. Key Features Essential for Efficiency

- 3. Safety Features to Prioritize

- 4. Durability and Build Quality

- 5. Customization Options for Specific Needs

- 6. Maintenance Requirements to Consider

- 7. Cost-Effectiveness and ROI

- 8. Frequently Asked Questions (FAQs)

- 9. Conclusion

1. Understanding the Mechanism of Double Shaft Shredders

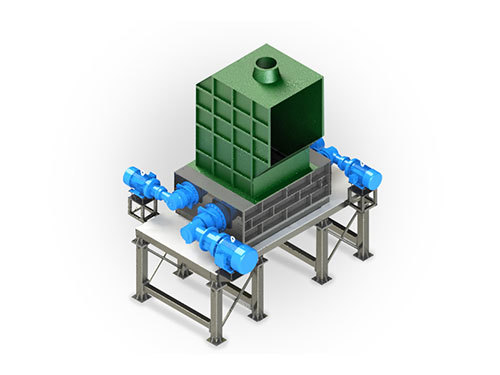

Double shaft shredders operate using a pair of rotating shafts equipped with sharp blades or hooks. These shafts rotate in opposite directions, allowing for a more aggressive shredding action. The design enables the machine to effectively tear apart tough materials while maintaining a controlled output size. Understanding this mechanism is crucial for selecting the right model to meet your operational needs.

2. Key Features Essential for Efficiency

When evaluating double shaft shredders, several features directly impact their efficiency:

2.1 Blade Design and Material

The **blade configuration** significantly affects the shredding capability. Look for:

- **High-quality steel blades**: Durable and resistant to wear.

- **Interchangeable blade options**: Allows for adjustments based on material type.

- **Optimized blade geometry**: Increases cutting efficiency and minimizes energy consumption.

2.2 Drive System

The drive system's performance is pivotal in ensuring consistent operation. Features to seek include:

- **High torque motors**: Essential for shredding dense materials.

- **Variable speed control**: Offers flexibility in handling different materials.

- **Robust gearbox design**: Ensures stability and reduces the risk of breakdowns.

3. Safety Features to Prioritize

Safety is paramount in any industrial operation. When selecting a double shaft shredder, consider models equipped with the following safety features:

3.1 Emergency Stop Mechanisms

Immediate shutdown capabilities are critical. Look for shredders with:

- **Accessible emergency stop buttons**: Easily reachable in crisis situations.

- **Automatic shut-off features**: Activated during malfunctions or overloads.

3.2 Protective Covers and Guards

Ensure that the shredder includes **full safety covers** and **guards** around moving parts to protect operators from accidents.

4. Durability and Build Quality

The longevity of a double shaft shredder largely depends on its build quality:

4.1 Frame Material

A sturdy frame typically made from **heavy-duty steel or reinforced materials** can withstand harsh operating conditions.

4.2 Load Capacity

Assess the shredder’s load capacity to ensure it meets your processing requirements. Higher capacity shredders are often built with **thicker materials** to handle increased stress.

5. Customization Options for Specific Needs

Double shaft shredders can often be tailored to meet specific needs:

5.1 Adjustable Screen Sizes

Choose models that allow for **screen size adjustments** to customize the output particle size based on different applications.

5.2 Additional Features

Some shredders come with options for:

- **Integrated conveyor systems**: Enhances material handling efficiency.

- **Shredding baskets**: Simplifies the collection of shredded materials.

6. Maintenance Requirements to Consider

Regular maintenance is vital for prolonging the lifespan of a double shaft shredder:

6.1 Ease of Access for Repairs

Select models designed for easy access during maintenance tasks. This feature can significantly reduce downtime and maintenance costs.

6.2 Scheduled Maintenance Support

Opt for manufacturers that provide comprehensive maintenance support, including:

- **Service contracts**: Ensure regular check-ups and repairs.

- **Spare parts availability**: Quick access to essential components.

7. Cost-Effectiveness and ROI

Investing in a double shaft shredder should be viewed through the lens of **cost-effectiveness**:

7.1 Initial Investment vs. Long-Term Savings

Consider the initial purchase cost in relation to long-term savings from operational efficiencies and reduced labor costs.

7.2 Energy Efficiency

Evaluate the energy consumption of different models. Choosing energy-efficient options can lead to significant savings on utility bills over time.

8. Frequently Asked Questions (FAQs)

8.1 What materials can be processed using a double shaft shredder?

Double shaft shredders can handle a variety of materials, including plastics, metal, wood, and organic waste.

8.2 How do I determine the right size of shredder for my needs?

Consider your typical material load and desired output size. Consult with manufacturers for recommended sizes based on your specific application.

8.3 Are double shaft shredders safe for operation?

Yes, when equipped with adequate safety features such as emergency stops and protective guards, double shaft shredders can be operated safely.

8.4 What is the average lifespan of a double shaft shredder?

With proper maintenance, a double shaft shredder can last upwards of 10-15 years, depending on usage and material types processed.

8.5 Can double shaft shredders be customized?

Yes, many manufacturers offer customization options to suit specific shredding needs, including adjustable screen sizes and additional features.

9. Conclusion

Investing in a double shaft shredder involves careful consideration of various features that directly influence efficiency, safety, and durability. By prioritizing high-quality blade design, robust safety mechanisms, and customizable options, you can ensure that your shredder will meet your operational demands. Additionally, understanding maintenance requirements and assessing the cost-effectiveness of your investment will lead to a machine that not only performs well but also provides a solid return on investment. In the ever-evolving landscape of waste management, selecting the right double shaft shredder is crucial for optimizing your operations and contributing to a more sustainable future.

double shaft shredder

News

Center

Contact us

Maanshan shengzhong heavy industry machinery co.,Ltd.

Address: Bowang Economic Development Zone, Bowang New District, Ma'anshan City, Anhui Province

Tel: 0555-6765308

Mobile: +8615385558866