Understanding Double Shaft Shredders: Key Insights for Manufacturing Professionals

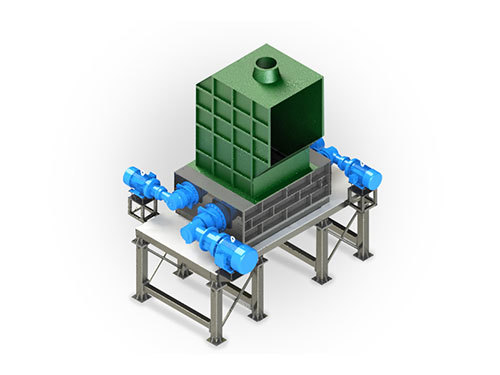

Double shaft shredders are crucial machines in the realm of manufacturing and processing, particularly for size reduction and material recycling. These machines utilize two parallel shafts, each equipped with sharp blades that rotate in opposite directions. This design is specifically engineered to shred a wide variety of materials, making it a versatile tool in various industrial applications.

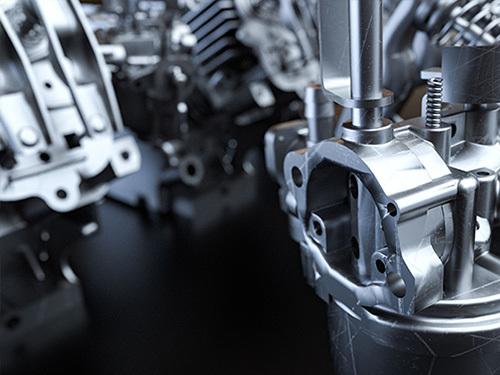

One of the primary benefits of double shaft shredders is their ability to handle tough materials, such as plastics, metals, wood, and electronic waste. Their robust construction allows them to effectively reduce large items into manageable sizes, which is essential for both recycling and waste management processes. The dual shafts work collaboratively to apply significant force on the materials, ensuring uniform shredding and minimizing the risk of jams and blockages.

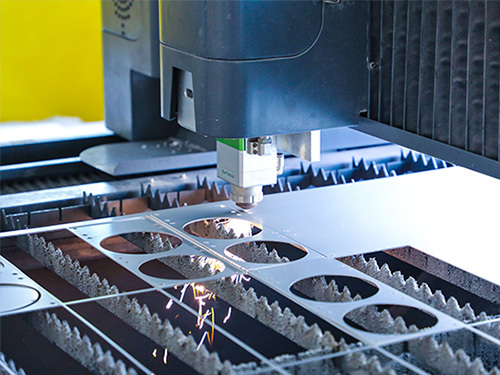

In terms of design, double shaft shredders are often equipped with advanced features such as variable speed control, which allows operators to adjust the shredding process based on the material being processed. This adaptability not only enhances efficiency but also prolongs the lifespan of the blades. Additionally, many double shaft shredders come with a built-in cooling system to prevent overheating during prolonged operation, which is crucial for maintaining optimal performance.

The applications of double shaft shredders are extensive. In the recycling industry, they are commonly used to process end-of-life products such as automotive parts, tires, and office waste. This capability helps reduce the volume of waste that ends up in landfills and promotes sustainable practices within the industry. Furthermore, their role in the manufacturing sector extends to the preparation of raw materials for further processing, thereby facilitating smoother production workflows.

When it comes to maintenance, regular inspections and blade replacements are vital for ensuring the longevity and effectiveness of double shaft shredders. Operators should be trained to recognize signs of wear and tear, which can help prevent costly downtime and maintain production efficiency. Additionally, investing in quality maintenance practices can enhance the overall performance of the machine.

In conclusion, double shaft shredders play an essential role in modern manufacturing and processing operations. Their ability to efficiently and effectively shred a wide range of materials makes them invaluable for recycling and waste management applications. Understanding the functionality, benefits, and maintenance needs of double shaft shredders can help professionals in the manufacturing industry optimize their operations and contribute to more sustainable practices. By incorporating these machines into their processes, companies can not only improve their operational efficiency but also support environmental stewardship.

One of the primary benefits of double shaft shredders is their ability to handle tough materials, such as plastics, metals, wood, and electronic waste. Their robust construction allows them to effectively reduce large items into manageable sizes, which is essential for both recycling and waste management processes. The dual shafts work collaboratively to apply significant force on the materials, ensuring uniform shredding and minimizing the risk of jams and blockages.

In terms of design, double shaft shredders are often equipped with advanced features such as variable speed control, which allows operators to adjust the shredding process based on the material being processed. This adaptability not only enhances efficiency but also prolongs the lifespan of the blades. Additionally, many double shaft shredders come with a built-in cooling system to prevent overheating during prolonged operation, which is crucial for maintaining optimal performance.

The applications of double shaft shredders are extensive. In the recycling industry, they are commonly used to process end-of-life products such as automotive parts, tires, and office waste. This capability helps reduce the volume of waste that ends up in landfills and promotes sustainable practices within the industry. Furthermore, their role in the manufacturing sector extends to the preparation of raw materials for further processing, thereby facilitating smoother production workflows.

When it comes to maintenance, regular inspections and blade replacements are vital for ensuring the longevity and effectiveness of double shaft shredders. Operators should be trained to recognize signs of wear and tear, which can help prevent costly downtime and maintain production efficiency. Additionally, investing in quality maintenance practices can enhance the overall performance of the machine.

In conclusion, double shaft shredders play an essential role in modern manufacturing and processing operations. Their ability to efficiently and effectively shred a wide range of materials makes them invaluable for recycling and waste management applications. Understanding the functionality, benefits, and maintenance needs of double shaft shredders can help professionals in the manufacturing industry optimize their operations and contribute to more sustainable practices. By incorporating these machines into their processes, companies can not only improve their operational efficiency but also support environmental stewardship.

double shaft shredder

News

Center

Contact us

Maanshan shengzhong heavy industry machinery co.,Ltd.

Address: Bowang Economic Development Zone, Bowang New District, Ma'anshan City, Anhui Province

Tel: 0555-6765308

Mobile: +8615385558866